The most recent information about LG Chem's $3 billion battery cathode facility that is being built in Tennessee for electric cars.

December 27: LG Chem’s battery cathode facility held its groundbreaking ceremony last week. The corporation has modified some of its initial goals.

Originally, the facility was scheduled to begin construction in Q1 2023 and begin mass production in the latter part of 2025. Thus, the production debut date has been rescheduled to “starting from 2026,” over a year after the groundbreaking.

Originally, LG Chem stated that by 2027, it would be producing 120,000 tons of cathode material yearly, which would be sufficient to power the batteries of 1.2 million electric vehicles with a 498 km/310-mile range between charges.

However, as of right now, the factory can only produce half of the initial 600,000 high-performance pure electric car cathode materials that were planned for each year.

Nonetheless, the company claims that in response to rising demand, it would “expand production capacity.”

Throughout October, Toyota and LG Chem agreed to a $2.5 billion contract for the supply of cathode materials throughout North America.

November 22, 2022: To construct a $3 billion cathode plant for electric cars, LG Chem and the state of Tennessee inked a memorandum of agreement.

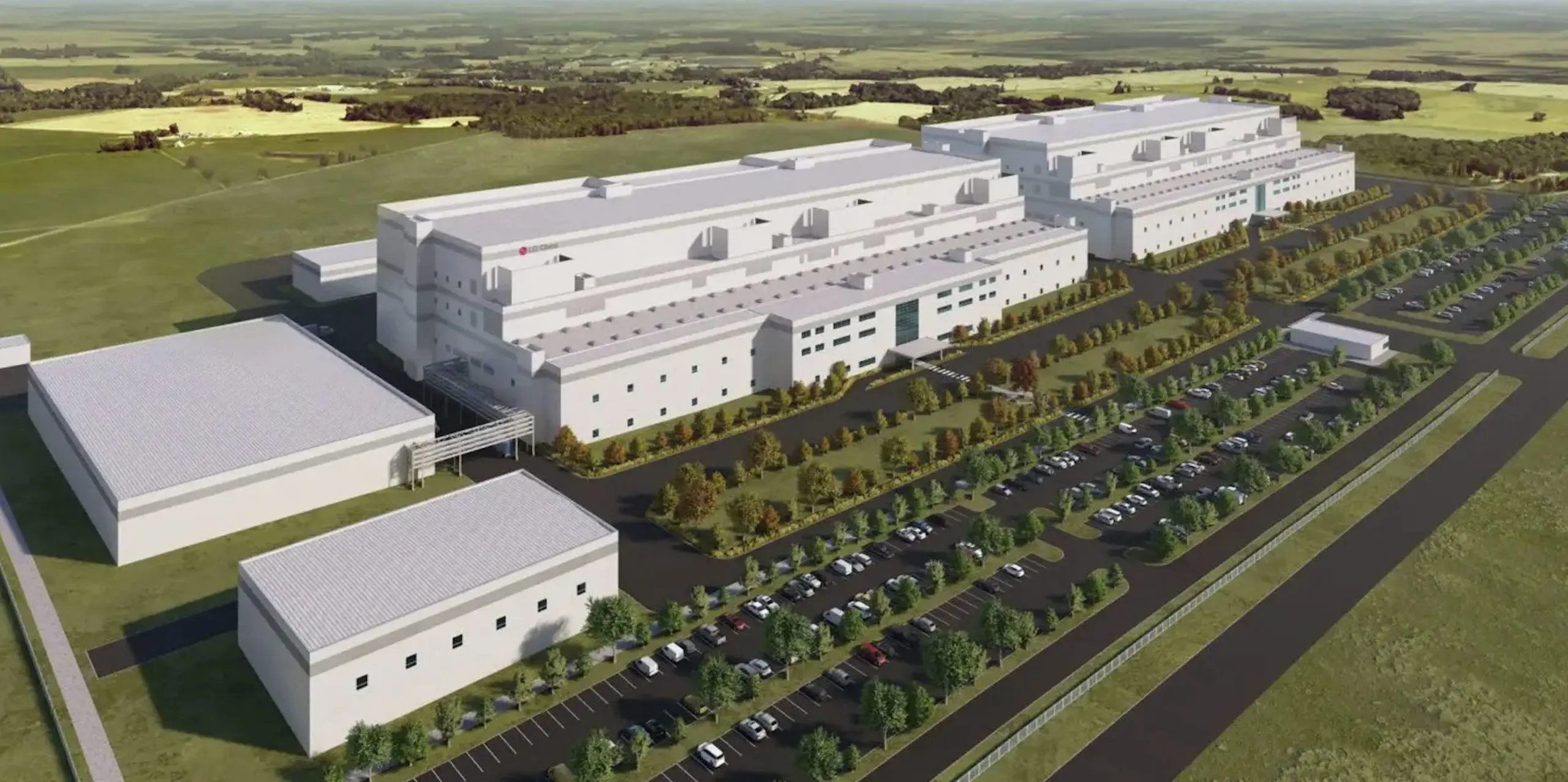

Situated near Clarksville, the new factory will be the biggest of its kind in the United States. By 2027, it is anticipated to generate 120,000 tons of cathode material yearly from its 420 acres of land. That is sufficient to run the batteries in 1.2 million electric vehicles for 498 km/310 miles between charges.

Tennessee was selected, according to LG Chem, due to its accessibility to important clients, the simplicity of transferring raw materials, and the support of regional and local authorities.

It also credits the Inflation Reduction Act (IRA) passed by the Biden administration with spurring the construction of the new factory, which will generate 850 employment.

Global clients like Tesla and General Motors will be supplied by material and recycling partners working together at Tennessee, according to LG Chem.