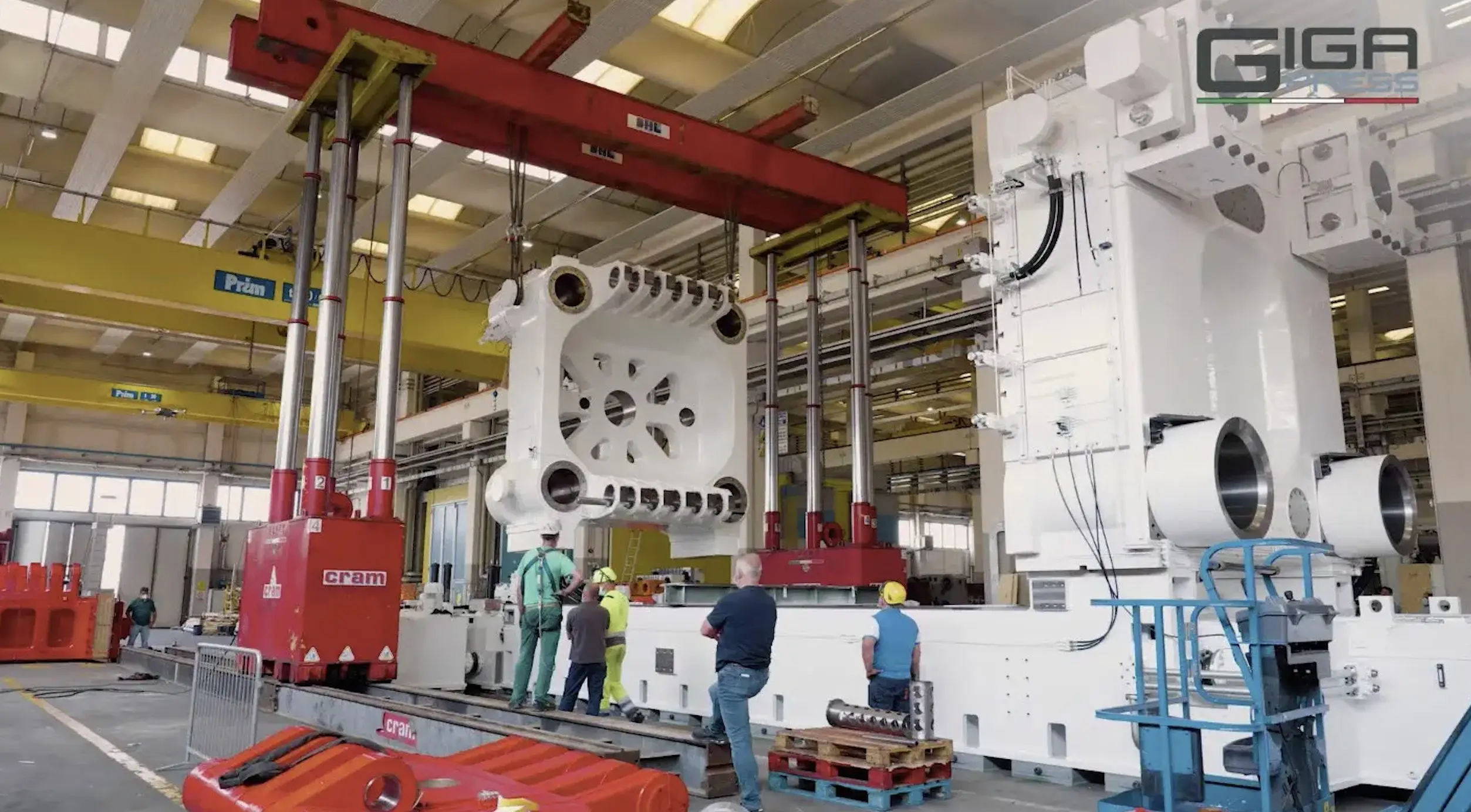

The chassis produced in one go instead of 400 different chassis parts will both increase production speed and reduce costs.

Tesla is preparing to produce the entire electric vehicle chassis in one piece.

The chassis produced in one go instead of 400 different chassis parts will both increase production speed and reduce costs.

Tesla Model Y’s chassis, which currently consists of a structural battery in the front, rear, and middle, will turn into a single piece. The true unibody chassis is expected to be used first in the cheap Tesla worth $ 25 thousand.

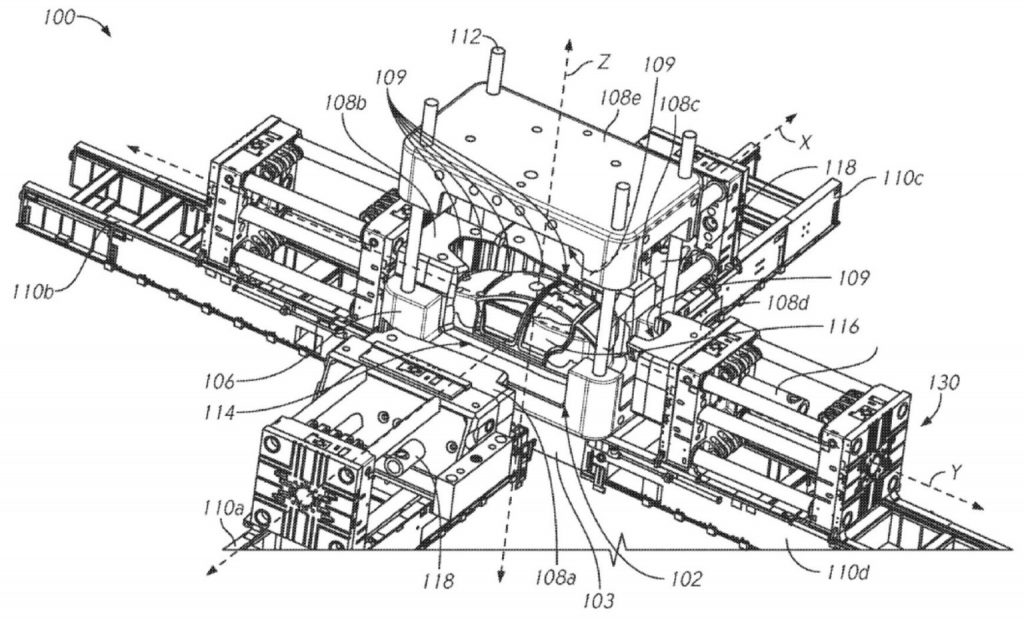

The molds to be used in the production of the monolithic chassis can be produced with 3D printers with industrial sand. Design approval time will decrease from 6-12 months to 2-3 months.

While the cost of a mold during the design changes of the vehicle from prototype to mass production can reach several million dollars, this cost will be reduced by almost 97% with the system that Tesla will adopt.

Yekpare şasiyi daha ucuz kalıplarda ve yüksek verimlilikle üretmek için özel alüminyum alaşımlar geliştiriliyor.