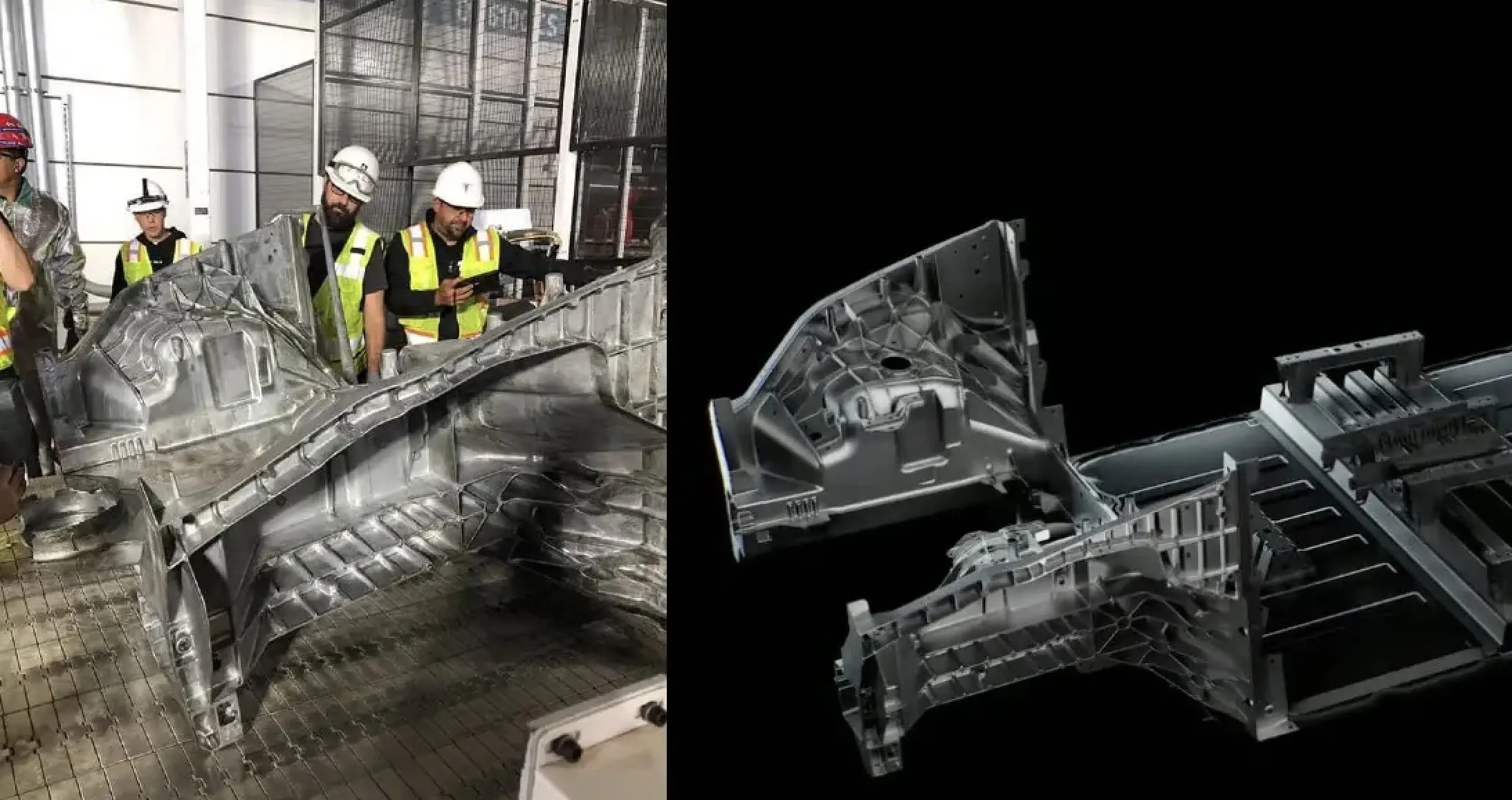

The one-piece chassis design pioneered by Tesla allows the production of lighter, more durable, cheaper, and faster vehicles.

The one-piece chassis design pioneered by Tesla allows the production of lighter, more durable, cheaper, and faster vehicles, but it raises questions about repairability.

According to the latest research published in England, Tesla has taken serious measures regarding the repairability of the rear chassis in light and medium-sized damage. In case of a complete chassis replacement, it is possible to obtain a new giant chassis from Tesla by paying a small fee of ~$900 + VAT. (Thatcham Research)

The one-piece chassis produced using 3 series aluminum can be welded in case of breaks of a certain size after an accident, and the resulting break does not prevent the vehicle from getting back on the road safely. However, the real problem in major accidents is the damage to the battery pack.

Damage to the battery pack in the event of an accident increases the risk of explosion and fire, as well as accelerating the loss of capacity of the battery. In this regard, it is very important that the one-piece chassis has high strength and that it does not bend and break in major accidents instead of crushing the battery pack, in order to protect the battery, which constitutes the largest part of the vehicle cost.

According to the forecast shared by S&P Global Mobility, the use of single-piece chassis instead of old-school chassis in the automobile market will reach 15-20% by 2030.